Rare Copper Specimens Tell a 9,500-Year Old Story

We will formally opened our new Native Copper exhibit in the Joe Webb Peoples Museum just before Bronze Day (April 26), the Wesleyan Archeology Group’s ‘Copper Culture Celebration’.

Native Copper Deposits

Copper is not a rare element on earth; copper deposits large and small occur in many places. Most of these are copper sulfides because Cu is a ‘sulphur loving’ element (chalcophilic). A rare form of Cu deposits are the native copper group or Cu⁰ which occur in only a few places in the world. Since Cu is chalcophilic, one could ask the question: how do native Cu crystals grow in nature? In our exhibit we show the richness in shapes and forms of the yellowish crystals of Cu.

The formation of native Cu deposits begins within Earth’s crust, where warm fluids (called hydrothermal fluids) circulate and dissolve elements from surrounding rocks. Relatively cool (several 100 degrees C) hydrothermal fluids (commonly percolating rainwater) dissolve Cu-ions (Cu1+ or Cu2+) from Cu-rich basalts. These same hydrothermal fluids react with Fe2+ bearing minerals (e.g., olivine and magnetite), oxidizing them into “rust” (Fe³+). At the same time, they reduce CO₂ into methane (CH₄) gas and water into H₂ gas in a process called “serpentinization”. These two gases and the Cu-ions are carried upwards together in the hydrothermal fluids. The dissolved Cu ions can become reduced by either of the two gases into native Cu (Cu⁰), which will precipitate out of the fluid as a solid crystal, filling in the cracks and openings in the cooled basalt flows. This process is a rare occurrence because the Earth’s crust has limited amounts of mobile reducing agents.

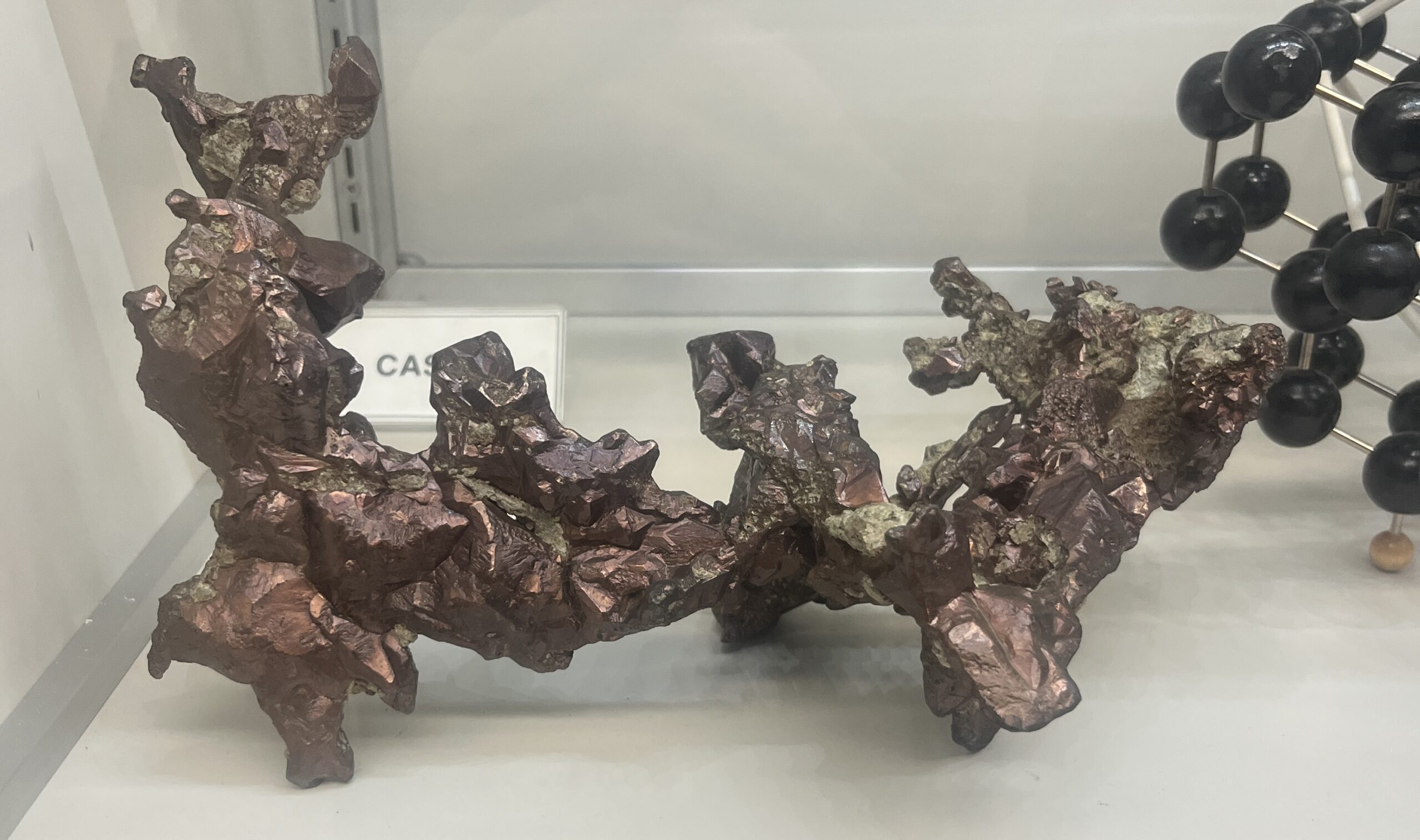

However, about one billion years ago in the Keweenaw Peninsula in the Lake Superior Region of Michigan, massive volumes of lava flows erupted, and the leaching of Cu and serpentinization of the basalt led to the ‘just right mixture.’ This led to the precipitation of native copper plaques in the cooled upper stack of the lava flows as well as in interbedded sedimentary rocks. This native Cu is additionally unique because of its form (or shape): native Cu crystals are typically cubes or octahedrons, but native Cu crystals in Keweenaw occur also as cubes with pyramids on each square face (called tetrahexahedrals; Boulliard et al., 2021). This unusual feature is not observed anywhere else in the world for Cu crystals.

Example of the unique tetrahexahedral shape of native Cu crystals. This sample is from Keweenaw Peninsula (the Franckfort Collection), on display in the Joe Webb Peoples Museum of Natural History.

Besides the Keweenaw peninsula, native Cu is found in Coro Coro, Bolivia; Ray Mine, Arizona; New South Wales, Australia; Itauz Mine, Kazakhstan; and Tsumeb, Namibia – just to name a few! Many of these occurrences are also associated with “serpentinite” masses.

From the 1840s to 1968, ~10.5 billion pounds of Cu were mined from the Keweenaw Peninsula (Bornhorst and Mathur, 2017), and the peninsula had the biggest Cu producing mines in the world. With the modern rise in Cu prices, new mines may start up again in the Keweenaw peninsula. Native American history tells us that not only is native Cu somewhat difficult to harvest, but it is also softer than other common materials, and therefore not the most effective for toolmaking and weaponry. Later trends were to make alloys of Cu and tin (Sn, bronze) or Cu and zinc (Zn, brass), which creates stronger metallic materials.

Human History of Native Copper: The Old Copper Culture

Ten years ago, our understanding of the timeline of old copper culture (OCC) – and relatedly, the history of Native American metalsmithing – was turned upside down. New trace element measurements and radiocarbon dates on Cu relics revealed Indigenous American groups began mining copper 9,500 years ago, and halted it ~5,000 years ago, respectively 5,000 years and 1,000 years earlier than formerly thought (Pompeani, 2015). This revelation put an increased focus on the OCC, a vibrant period of copper tool production by archaic Indigenous American groups (e.g. Pompeani et al. 2021). Previously, researchers held a common notion that once a society developed metal tools, they wouldn’t return to stone; however, archaeological and geochemical findings now suggest that archaic Indigenous American groups may have done just that (e.g. Bebber et al. 2021).

The OCC largely occurred around the Great Lakes, particularly in the Keweenaw Peninsula in the Lake Superior Region of Michigan. Here, native copper (Cu) deposits were abundant. Indigenous American groups took advantage of this and mined Cu ores to create metal tools, weapons, and jewelry. The most common artifacts found from this period include arrowheads, knives, and awls, and for thousands of years, these Cu items were in common use (e.g. Malakoff, 2021). To place these artifacts in the OCC timeline, Pompeani et al. 2021 employed radiocarbon dating. Unexpectedly, the researchers found that ~5,000 years ago, Native American groups seemingly abandoned their Cu tools again (except for the awls; Bebber et al. 2021). They returned to using stone and bone for their tools because these materials were easier to harvest and had a similar hardness as native Cu. Following the OCC, Cu was mostly used for jewelry and became more of a symbol of wealth.

Replicas of copper arrows and tools originally made by Native Americans during the Old Copper Complex. These replicas were made by Dr. Michelle Bebber, Kent State University. Image acquired via David Malakoff/Science, who acquired the image from Dr. Bebber.

Indigenous Americans likely weren’t the only people smelting copper at this time. Muşkara et al. (2025) identified a piece of melted soil and copper in Gre Filla, Anatolia, Turkey that may have been smelted by hunter-gathers ~10,800 years ago. Whether the object is a piece of smelted Cu isn’t confirmed (some researchers suggest the melting may have been unintentional (Mehra, 2025)), but nonetheless, there is a chance indigenous groups in North America and the Middle East began smelting Cu around the same time – entirely independently! This begs the question: was a bigger influence involved? Some archaeologists have suggested climate shifts may have been a driving force (Malakoff, 2021).

Copper Mining Today

Nowadays, Cu is used to a large degree for the transfer of electricity: Cu wiring, electric motors and more. The demand for Cu has increased manyfold compared to the early 1900’s and the “new source” of Cu are now the so-called porphyry Cu deposits, found in close association with subduction volcanoes (Andes, Indonesia, ancient subduction zones in AZ-UT). Porphyry Cu deposits form when a close to granitic magma exsolves a sodium chloride (NaCl)-rich brine that plays host to volatile copper compounds (this happens at 800-900 oC!). Sulfur-rich volcanic gases rising from greater depth bubble through the granitic magma and interact with the brine phase and then precipitate the typical porphyry copper mineral chalcopyrite (CuFeS2). While ancient native Cu mines now stand largely deserted, porphyry Cu deposits are mined in giant open pit mines of altered volcanic rock. The many small, dispersed chalcopyrite crystals are first separated from the rock matrix and then smelted to separate the Cu from the Fe and S (a messy and highly polluting process). Other common Cu minerals occasionally mined when present in great abundance are deep blue azurite (Cu₃(CO₃)2(OH)2), grass green malachite (Cu2CO₃(OH2)), and silvery chalcocite (Cu2S).

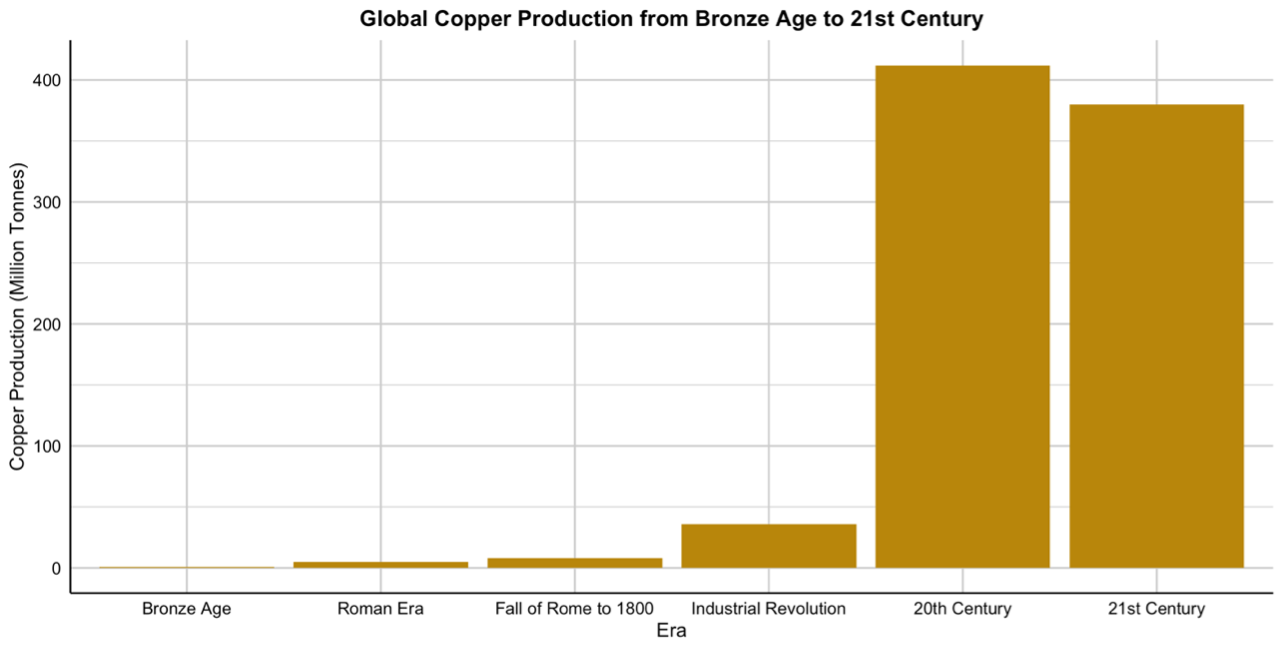

The transition in Cu mining from Native Cu to Cu sulfides followed fluctuations in Cu demand through World War I, the Great Depression, and World War II (National Park Service). During World War I, large quantities of copper were needed to manufacture vehicles and ammunition. This spurred the development of new technologies to dig quicker and deeper. However, this demand quickly declined during the Great Depression, and many copper mines closed. When World War II began, the demand for copper spiked once again, but that quickly ended again in 1945. By 1997, all industrial copper mines on the Keweenaw Peninsula were closed (National Park Service), and the copper economy instead expanded internationally.

Graph of world copper production. Data synthesized by The Copper Knowledge Base and from Hong et al. (1996) and Fizaine et al. (a, b, 2021).

The Joe Webb Peoples Museum Native Copper Exhibit

Our new exhibit displays many specimens from the Franckfort collection, which was purchased by Wesleyan University in 1857 and features many samples from the Keweenaw Peninsula. Dr. Eugene Franckfort was an accomplished mining engineer; he served as a copper mine director in Italy and notably discovered a lead-zinc mine in Verbania.

In 1871, Wesleyan’s Natural History Museum, the Orange Judd Hall of Natural Sciences, opened, and numerous cabinets were displayed. Today, the museum has been renamed to the Joe Webb People’s Museum of Natural History and is located on the fourth floor of Wesleyan’s Exley Science Center. Our new Cu exhibit displays native copper (Cu; cubic structure and yellow color) as well as chalcopyrite (CuFeS2; tetragonal structure and bronze color), malachite (Cu2CO₃(OH)2; monoclinic structure and deep green color), and azurite (Cu₃(CO₃)2(OH)2; monoclinic structure and deep blue color) to show the great variety of copper species. Native Cu specimens are all the same mineral, but they take on different crystalline shapes and have various weathering colors. You might have seen colorful, weathered Cu before in many giant copper cupolas on Renaissance churches! We invite you to visit the exhibit in person Monday through Friday from 9:00am-4:00am EST. We especially invite you to visit during the Wesleyan archaeology group’s Bronze Day celebration. Learn more HERE.

Our new native copper exhibit, located at the Joe Webb People’s Museum of Natural History in Wesleyan University’s Exley Science Center.

References

Cornellrockey (2006). The Lavender Pit, an open pit copper mine, Brisbee, Arizona. Uploaded to

Wikipedia Commons on April 19, 2008.

Bebber, M.R. (2021). The Role of Functional Efficiency in the Decline of North America’s

Copper Culture (8000–3000 BP): an Experimental, Ecological, and Evolutionary

Approach. J Archaeol Method Theory 28, 1224–1260.

Boulliard, J.-C., Aléon, J., & Gaillou, E. (2021). On the anomalous shapes of native copper

crystals from the Michigan Copper Country. European Journal of Mineralogy, 33(1), 9–21

Fizaine, F., & Galiegue, X. [a] (2021). L’économie des ressources minérales et le défi de la

soutenabilité. ISTE éditions.

Fizaine, F., & Galiègue, X. [b] (2021). L’économie des Ressources Minérales et le défi de la

Soutenabilité 2: Enjeux et Leviers D’action. ISTE éditions.

Hong, S., Candelone, J.-P., Patterson, C. C., & Boutron, C. F. (1996). History of Ancient Copper

Smelting Pollution During Roman and Medieval Times Recorded in Greenland Ice.

Malakoff, D. (2021). Ancient Native Americans were among the world’s first coppersmiths.

Mehra, S. (2025). This lump of melted soil may push the origin of metallurgy by thousands of

Muşkara, Ü., Bozbaş, S. K., Telli, M. B., & Konak, A. (2025). Early copper production by the

last hunter-gatherers. Journal of Archaeological Science: Reports, 62, 105051.

National Park Service. (2024). Timeline of Copper Mining. Keweenaw.

Pompeani, D. (2015) Human impacts on the environment over the Holocene in Michigan and

Illinois using lake sediment geochemistry. Doctoral Dissertation, University of

Pompeani, D. P., Steinman, B. A., Abbott, M. B., Pompeani, K. M., Reardon, W., DePasqual, S.,

& Mueller, R. H. (2021). ON THE TIMING OF THE OLD COPPER COMPLEX IN

NORTH AMERICA: A COMPARISON OF RADIOCARBON DATES FROM

DIFFERENT ARCHAEOLOGICAL CONTEXTS. Radiocarbon, 63(2), 513–531.

Singer, D.A. Long-Term Copper Production to 2100. Math Geosci 56, 711–722 (2024).

The Copper Knowledge Base. (2023). How much copper has been mined since the dawn of

mankind? The Copper Knowledge Base.